|

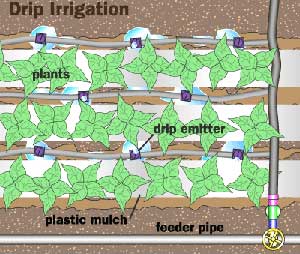

Drip Irrigation

Need of the Time

Introduction

Drip irrigation is the most efficient method of

irrigating. While sprinkler systems are

around

75-85% efficient, drip systems typically are 90% or higher.

What that means is much less wasted water! For this reason

drip is the preferred method of irrigation in the desert

regions of the United States. But drip irrigation has other

benefits which make it useful almost anywhere. It is easy to

install, easy to design, can be very inexpensive, and can

reduce disease problems associated with high levels of

moisture on some plants. If you want to grow a rain forest,

however, drip might not be the best choice! around

75-85% efficient, drip systems typically are 90% or higher.

What that means is much less wasted water! For this reason

drip is the preferred method of irrigation in the desert

regions of the United States. But drip irrigation has other

benefits which make it useful almost anywhere. It is easy to

install, easy to design, can be very inexpensive, and can

reduce disease problems associated with high levels of

moisture on some plants. If you want to grow a rain forest,

however, drip might not be the best choice!

Drip irrigation (sometimes called trickle irrigation) works by

applying water slowly, directly to the soil. The high

efficiency of drip irrigation results from two primary

factors. The first is that the water soaks into the soil

before it can evaporate or run off. The second is that the

water is only applied where it is needed, (at the plant's

roots) rather than sprayed everywhere. While drip systems are

simple and pretty forgiving of errors in design and

installation, there are some guidelines that if followed, will

make for a much better drip system. The purpose of this

tutorial is to guide you toward materials and methods that

will increase the benefits of your new drip system, while

steering you away from some common misconceptions and

practices that can cause you trouble.

Why would you want to consider drip irrigation?

Drip irrigation can be a great aid to the efficient use of

water. A well designed drip irrigation system or subsurface

drip irrigation system will lose practically no water to

runoff, deep percolation or evaporation. Irrigation scheduling

can be precisely managed to meet crop demands, holding the

promise of increased crop yields and quality.

Drip irrigation will decrease water contact with crop leaves,

stems, and fruit. Thus conditions may be less favorable for

the onset of diseases. Often growers or irrigation

professionals refer to "subsurface drip irrigation" or SDI.

When the drip tube can be buried below the soil surface, it is

less vulnerable to damage during cultivation or weeding. Water

use can be managed to be very efficient with SDI because

irrigations can avoid water losses to evaporation, runoff, and

wetting the soil below the root zone.

Agricultural chemicals can be used more efficiently with drip

irrigation. Since only the crop root zone is irrigated,

nitrogen already in the soil is less subject to leaching

losses. Fertilizer N that is added can be used more

efficiently. Where insecticides are labeled for application

through drip irrigation, less insecticide may be required to

control pests.

With all the potential benefits of drip irrigation, conversion

to drip irrigation can increase production costs, especially

where another pre-existing irrigation system is already in

place. Ultimately, there must be an economic advantage to the

growers for them to consider drip irrigation.

Advantages of drip irrigation

1. Drip is adaptable to fields with odd shapes or

uneven topography. Drip irrigation can work well where other

irrigation systems are inefficient because parts of the field

have excessive infiltration, water puddling, or runoff.

2. Drip irrigation can be helpful if water is scarce or

expensive.

Drip

irrigation has become common where water is very scarce or

where water is very expensive to pump. Precise water

application is possible with drip irrigation. Irrigation with

drip can be more efficient because evaporation is reduced,

runoff is reduced or eliminated, deep percolation is reduced,

and irrigation uniformity is improved so it is no longer

necessary to "over water" parts of a field to adequately

irrigate the more difficult parts. Drip

irrigation has become common where water is very scarce or

where water is very expensive to pump. Precise water

application is possible with drip irrigation. Irrigation with

drip can be more efficient because evaporation is reduced,

runoff is reduced or eliminated, deep percolation is reduced,

and irrigation uniformity is improved so it is no longer

necessary to "over water" parts of a field to adequately

irrigate the more difficult parts.

3. Precise application of nutrients is possible using

drip irrigation. Fertilizer costs and nitrate losses can be

reduced. Nutrient applications can be better timed to plants'

needs.

4. Drip irrigation systems can be designed and managed

so that the wheel rows are sufficiently dry so that tractor

operations can occur at any time at the convenience of the

producer. Timely applications of herbicides, insecticides, and

fungicides is possible.

5. Proven yield and crop quality responses to drip

irrigation have been observed in onion, broccoli, cauliflower,

lettuce, melon, tomato.

6. A drip irrigation system can be automated. For an

example of automated drip irrigation.

Disadvantages of drip irrigation

1. Drip irrigation systems typically cost $500 to $1,200

per acre. Part of the system cost is a capital investment

useful for several years and part of the cost is annual.

Systems can easily be over designed. Growers without

experience may want to start with a relatively simple system

on a modest acreage and gain experience.

2. Drip tape has to be managed to avoid leaking or

plugging. Drip emitters can easily be plugged by silt or other

particles not filtered out of the irrigation water. Emitter

plugging also occurs by algae growing in the tape and chemical

deposits at the emitter. Tape depth will have to be carefully

chosen for compatibility with other operations such as

cultivation and weeding.

3. The weed control program may need to be redesigned.

Compatibility with weed control programs can be a problem if

herbicides need rainfall or sprinkler irrigation for

activation. But, drip irrigation can enhance weed control by

keeping much of the soil surface dry.

4. Drip tape disposal or reuse needs to be planned and

will cause extra clean up costs after harvest.

Components and design of a drip irrigation system

A

wide range of components and system design options is

available. The Digital Drip Directory provides lists of

equipment and their suppliers. Tape, depth of tape placement

in the soil, the distance between tapes, emitter spacing and

flow, and irrigation management must all be carefully chosen

to meet crop water requirements and the soil's properties.

Emitter spacing depends on the crop root system and soil

properties. Seedling plants such as onions have relatively

small root systems, especially at the beginning of the season.

The wetting pattern of water in the soil from the drip

irrigation tape must reach those roots. A

wide range of components and system design options is

available. The Digital Drip Directory provides lists of

equipment and their suppliers. Tape, depth of tape placement

in the soil, the distance between tapes, emitter spacing and

flow, and irrigation management must all be carefully chosen

to meet crop water requirements and the soil's properties.

Emitter spacing depends on the crop root system and soil

properties. Seedling plants such as onions have relatively

small root systems, especially at the beginning of the season.

The wetting pattern of water in the soil from the drip

irrigation tape must reach those roots.

1. Drip tape varies greatly in its specifications depending on

the manufacturer and its use (Table 1).

Table 1. Drip Tape Specifications by Manufacturer

(adapted from Hansen, et al., 2000)

|

Manufacturer

(Drip Tape Name)

|

Diameter (inches)

|

Wall Thickness (mil)

|

Emitter Spacing

(in)

|

Emitter Flow Rates (gal/h)

|

Chapin Watermatics

(Twin Wall) |

5/8, 7/8 |

4, 6, 8, 10, 15, 20, 25

|

2, 4, 6, 9, 12, 16, 24 |

.15-.60 |

|

Drip Tape Man. and Eng. Inc. (Tiger Tape)

|

5/8, 7/8

|

5, 6, 7-8, 10, 15

|

4 1/4, 8 1/2, 12 3/4, 17 1/4

|

.15, .21, .28

|

|

Eurodrip

|

5/8, 7/8

|

|

Customized

|

.31, .40, .65

|

|

Nelson Irrigation Corp. (Pathfinder)

|

5/8, 7/8,

1 3/8 |

5, 6, 8, 10, 15, 20 |

4, 8, 12, 16, 24

|

.13, .27, .37

|

|

Netafim (Streamline, Typhoon)

|

5/8, 7/8, 1

|

6, 8, 10, 13, 15

|

8, 12, 16, 24, 30

|

.16, .21, .33

|

|

Queen-Gil

|

1/2, 5/8, 13/16

|

6, 8, 12, 16

|

4, 8, 12, Variable

|

.05, .11, .21, .26, .31, .42, .46, .71

|

|

Roberts Irrigation Products (RO-DRIP)

|

5/8, 7/8

|

5, 6, 8, 10, 13, 15

|

4, 8, 12, 16, 24

|

.11, .24, .34

|

|

T-Systems International

(T-Tape)

|

3/8, 5/8, 7/8/, 1 3/8

|

4, 6, 8, 10, 15

|

4, 8, 12, 16, 18, 24

|

.14, .20, .27, .34, .40

|

|

ToroAg

(Aqua-Traxx)

|

5/8, 7/8 |

4, 6, 8, 10, 12, 15

|

4, 8, 12, 16, 24

|

.13, .20, .27

|

2. Distribution system, valves, and pumps must match

the supply requirements of the tape.

3. Design must take into consideration the contour:

elevation, pressure, and flow requirements. Design for water

distribution uniformity by carefully considering the tape,

irrigation lengths, topography, and the needs for periodic

flushing of the drip tape. Vacuum relief valves need to be

designed into the system.

4. Power and water source limitations need to be

considered. Water should be analyzed by a laboratory that is

qualified to evaluate emitter plugging hazards.

5. Water quality may provide limitations and increase

system costs. Filters must match worst case scenarios.

6. Injectors for chemigation should be included.

7. Flow meters are necessary to confirm system

performance

Management of drip irrigation

1. Plan for seed emergence. The drip tape needs to be

sufficiently near the surface to germinate the seed if

necessary, or a portable sprinkler system needs to be

available. For example, SDI with the tape tube 4 to 5 inches

deep has been used successfully to germinate onion seeds in

silt loam soil. Deep placement of drip tape at 12 inches

failed

to

uniformly germinate onions. to

uniformly germinate onions.

2. Water requirements for irrigation are reduced

because water can be applied vastly more efficiently with a

drip irrigation system. For example, with furrow irrigation

systems, typically 4 acre-feet/acre or more of water is

applied to onion fields in the Treasure Valley of eastern

Oregon and southwestern Idaho. Depending on the year, summer

rainfall, and the soil, 14 to 28 acre-inch/acre of water has

been needed to raise onions under drip irrigation in the

Treasure Valley. Drip irrigation with more water than a

plant's requirement will result in the loss of most of the

drip irrigation benefits. The soil will be excessively wet

promoting disease, weed growth, and nitrate leaching.

3. Use both measurements of soil water and estimates of

crop water use called "crop evapotranspiration" or "ETc".

Irrigate only to replace the soil moisture deficit in the top

12 inches of soil. It is usually not necessary to exceed ETc .

For our local crop production area, the daily crop

evapotranspiration estimates at Ontario are made automatically

on a daily chart by the AgriMet station.

4. Chlorine or other chemicals need to be added

periodically to the drip line to kill bacteria and algae in

the drip lines. Acid may be needed periodically to dissolve

calcium carbonates.

5. Filters must be managed. In spite of filtration,

drip tape must be flushed, with a frequency that is dependent

on the amount and kinds of sedimentation in the tape.

6. If irrigation is managed closely to meet plant water

needs, nitrogen fertilizer requirements are reduced because

nitrate leaching is reduced or nearly eliminated. Total

nitrogen requirements are reduced using drip irrigation and

less nitrogen should be applied in each application. Our

experience is that if fertilizer nitrogen applications are not

reduced, an onion crop under drip irrigation will become

excessively leafy. The leaves can inhibit curing and increase

harvest costs and increase harvest losses.

7. Fertilizers containing sulfate, phosphate, calcium,

or anhydrous or aqua ammonium can lead to solid chemical

precipitation inside the drip tape. The precipitates can block

emitters. Seek chemical analyses of your irrigation water and

competent technical advice before injecting chemical

fertilizers into drip tape.

8. Root intrusion needs to be controlled for some

crops.

9. Rodents must be controlled, especially where drip

tape is buried to provide irrigation for a number of years.

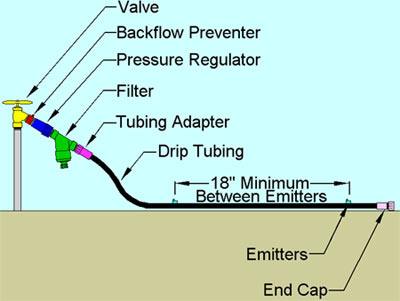

The Basic Parts of a Drip

System:

Valve-

Use any valve you want! They can be automatic or manual. If

you use an anti-siphon valve it has a built-in backflow

preventer which saves money! (But be sure to read up on

backflow preventers first, as anti-siphon valves won't work in

some places. For more

information

on valves. information

on valves.

Backflow Preventer-

You need to use a backflow preventer on ALL drip systems. No

exceptions! For more information on backflow preventers.

Pressure Regulator-

Most drip systems will need a pressure regulator. You need one

if your water pressure is over 2,8 bars (40 PSI). If in doubt,

install one. The regulator can go before or after the valve.

Traditionally it is installed after the valve.

Filter-

You must use a filter. Drip emitters have very small openings

that are easily clogged. City water is not free from stuff

that will clog your emitters! Use a 150 mesh screen or one

with a higher mesh number like 200 mesh. The filter may be

installed before the valve or pressure regulator, but the

inexpensive plastic filters often sold for drip systems should

be installed after the pressure regulator. I like to use a top

quality filter and install it right at the water source so it

protects the valves and the pressure regulator too. Most valve

failures result from sand or rust particles clogging of the

tiny passages inside the valve! Use a filter that is the same

size as, or larger than, the valve.

Emitters-

Most emitters emit 4 liters/hour (4,0 l/hr) of water. That's

about 1 gallon per hour (1 gph). I prefer a lower flow rate

than that, and use mostly 2,0 l/hr (0.6 gph, often referred to

as "1/2 gallon per hour") emitters on my drip system designs.

Use pressure compensating emitters if you are irrigating a

hilly area. There are many different types and brands

available.

Multi-Outlet emitters are very popular. They also suck!

(That's a personal opinion, based on years of observation.)

Use single outlet emitters for a less troublesome drip system.

Mainline-

The mainline is the pipe that goes from the water source to

the valves. In the illustration of a very simple drip system

above the gray colored vertical pipe under the valve is a

mainline. The mainline may be made of galvanized steel,

copper, SCH 40 PVC, SCH 80 PVC, Cl 315 PVC, Heavy Wall

Polyethylene (SDR 7 or SDR 9). Do not use polyethylene for the

mainline unless approved by your local building officials.

Polyethylene has a low burst pressure and should only be used

for mainlines where local conditions are appropriate.

Sub-Main-

The sub-main is the pipe that goes from the valves to the

connection point of the drip tube. Many small drip systems do

not have a sub-main, in those systems the drip tube connects

directly to the valve The illustration of a very simple drip

system above shows a system without a sub-main. Sub-mains are

usually Cl 200 PVC pipe or standard weight polyethylene (poly)

pipe. You use a sub-main when multiple drip tubes are needed.

Drip Tubing-

Drip tubing is a thin wall polyethylene tube, and is generally

produced in metric sizes. Common sizes are 12 mm (0.455" or

3/8"), 16mm (0.620" or 1/2"), 18mm (0.720" or 1/2"), and 24mm

(0.940" or 3/4"). Do you see the problem? Two sizes are

commonly referred to as "1/2 inch" in the USA! The fittings

for these two are not interchangeable. So make sure you know

what you're getting when you buy it! Do not bury drip tubing

underground- gophers and moles love to chew buried tubing!

Adapters and fittings-

Used to attach the drip tube to the other parts. Important-

make sure the fittings are the exact right size! Using

fittings made for a different tubing size will result in the

tube blowing out of the fitting. 9 times out of 10, when a

tube blows out of a fitting it is because the fitting is the

wrong size.

End Cap-

The end cap is important. Without it the water all runs out

the end of the drip tube.

Additional Resources:

Drip Irrigation for Row Crops. 1994. Chanson, Schwankl,

Grattan, and Prichard, University of California, Davis. Order

from Cooperative Extension office, Department of LAWR, 113

Veihmeyer Hall, University of California, Davis, CA 95616,

telephone (530) 752-1130.

B.C. Trickle Irrigation Manual. 1999. Van der Gulik,

B.C. Ministry of Agriculture and Food Resource Management

Branch. Order from Irrigation Association of British Columbia,

2300 Woodstock Drive, Abbotsford, B.C., Canada, V3G 2E5,

telephone (604) 859-8222.

Fertigation, 1995, Burt, O'Connor, and Ruehr,

California Polytechnic State University. Order from The

Irrigation Training and Research Center, California

Polytechnic State University (Cal Poly), San Luis Obispo, CA

93407, telephone (805) 756-2434.

Microirrigation Management and Maintenance. 1998.

Hassan, Farouk A.. Fresno, CA, Agro Industrial Management,

1998. The book is available from Farouk A. Hassan, Ph.D.

Irrigation & Soils Consultant, Agro Industrial Management, P.

O. Box 5632, Fresno, California 93755, U.S.A. Phone:

(209)224-1618, Fax: (209) 348-0721,

References:

- Irrigationtutorials.com (Jess

Stryker's )

- Malheur Experiment Station (Clinton

C. Shock)

Oregon State University

Edit by M. Irfan

|

Pakissan.com;

|